Proper power is critical for safe and reliable spindle operation. Below are the requirements for both 110V and 220V systems.

⚡ 110V Spindle Systems (1.5kW)

Our 110V 1.5kW spindle systems draw approximately 12 amps under load.

That means:

-

They can run on a standard 15A 110V circuit

-

The circuit must be dedicated to the spindle and VFD only

Why Dedicated?

12A is roughly 80% of a 15A breaker’s capacity.

According to the National Electrical Code (NEC), 80% is the maximum continuous load allowed on a circuit.

⚠️ Do not share this circuit with:

-

Dust collectors

-

Shop vacs

-

Air compressors

-

Heaters

Voltage sag from shared loads can cause VFD faults.

If Installing a New 110V Circuit

Ask your electrician for:

-

20A, 110V circuit

-

NEMA 5-20R outlet

-

12-gauge wire or larger

Even though the spindle uses ~12A, a 20A circuit gives better headroom and stability.

Included Power Cable (110V)

Your system includes:

-

NEMA 5-15P plug → IEC C13 connector

-

6 ft length

This works on both 15A and 20A 110V outlets.

⚡ 220V Spindle Systems (2.2kW)

Our 220V spindle systems draw approximately 10 amps under load.

220V operation is generally more stable and more forgiving under heavy cutting loads.

Recommended Circuit

If installing new:

-

20A, 220V circuit

-

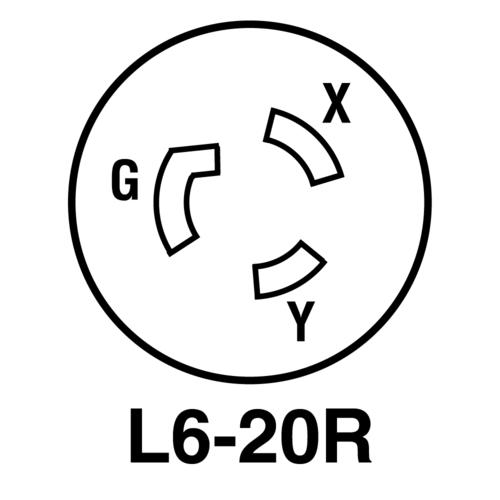

NEMA L6-20R outlet

Included Power Cable (220V)

Your system includes:

-

NEMA L6-20P plug → IEC C13 connector

-

6 ft length

🌍 International Customers

All 220V systems ship with a U.S. L6-20P plug.

If you are outside the U.S., you may:

-

Replace the plug with one compliant with your local standards

-

Replace the entire cable with a locally sourced IEC C13 cable rated for at least 15A at 220V

C13 cables are commonly used for servers and industrial electronics.

⚠️ Important Notes for Both 110V & 220V

-

Do not run spindles from extension cords unless they are properly rated.

-

Avoid GFCI circuits when possible, VFDs can cause nuisance tripping.

-

Stable voltage equals stable spindle performance.

If you're unsure about your electrical setup, consult a licensed electrician.